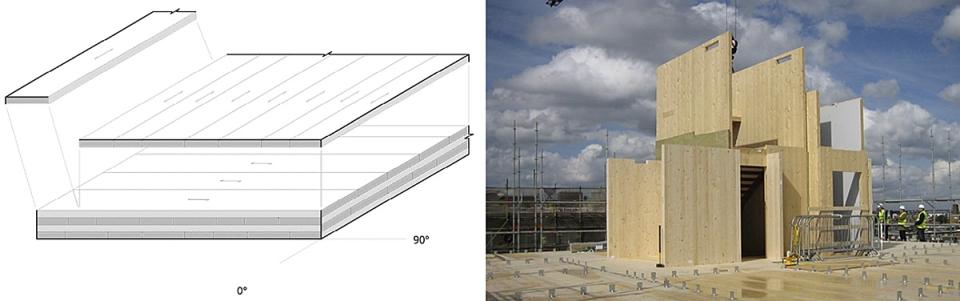

Cross laminated timber (CLT) are flat solid wood products that can be used as structural elements. Thanks to its favorable environmental, aesthetic and energy properties, it is sometimes called the material of the future.

The innovative board-shaped product with a laminated structure and interesting physical-mechanical properties consists of at least 3 board layers glued alternately at 90 degrees to each other. The individual boards are mainly 40 mm to 300 mm wide and 6 mm to 45 mm thick.

CLT boards are nothing new, they have been produced since 1995 but have not been included in standards until now. Their use in the construction industry was regulated by technical guidelines at European level (ETA: European Technical Assessment). With the second generation of Eurocode 5, CLT will immediately become part of that same standard, so that structural engineers finally have a way to design and test such structures in accordance with the standard. In the draft version of the new Eurocode 5, expected around 2025, CLT is woven into every check (where applicable) of the standard.

The application possibilities of CLT plates are quite broad. The load-bearing properties can be used to act as:

- Floor element

- Roof element

- Wall element

- Rib-element of a floor

- ...

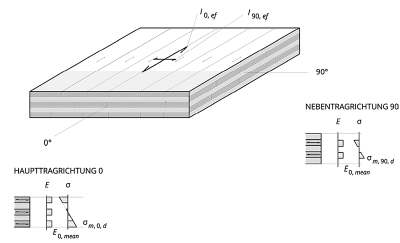

CLT panels are orthotropic because the load-bearing properties are different in the two directions (0° and 90°). This is a direct consequence of the number of plates and the positioning of the plate elements in a respective direction. The figure below illustrates the orthotropy using the bending stresses in both directions (0° = main bearing direction, 90° secondary bearing direction):

For the bending stresses, only the layers oriented in the respective direction are taken into account. The layers oriented in the other direction act as spacers and are only loaded on shear in the main load direction.